Dosing system ET 800 / 1000

The dosing system ET 800 is a mobile, compact machine for the facilitation and automation of manual dosing processes. Thanks to the low space requirement of only 1.5 m² as well as the four rollers and adjustable working height of the total machine, it can be used universally and in almost every production. The greatest advantage, compared to manual single dosing, is the automated dosing process with plannable cycle times, resulting in more time available for the operator to monitor the process and simultaneously carry out further work steps.

The ideal completement

Compact and mobile

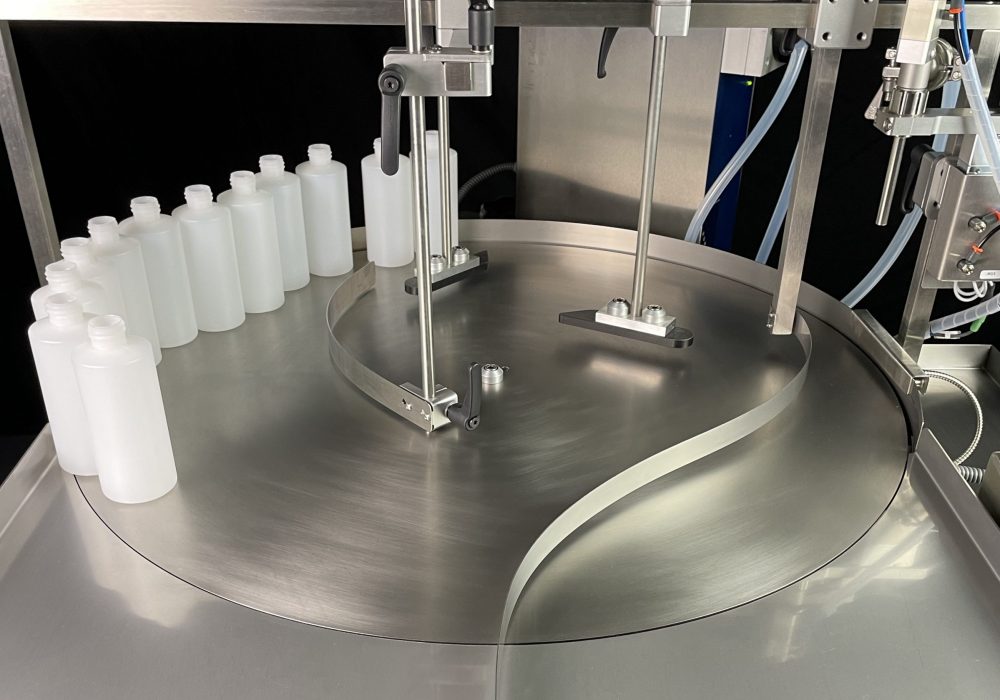

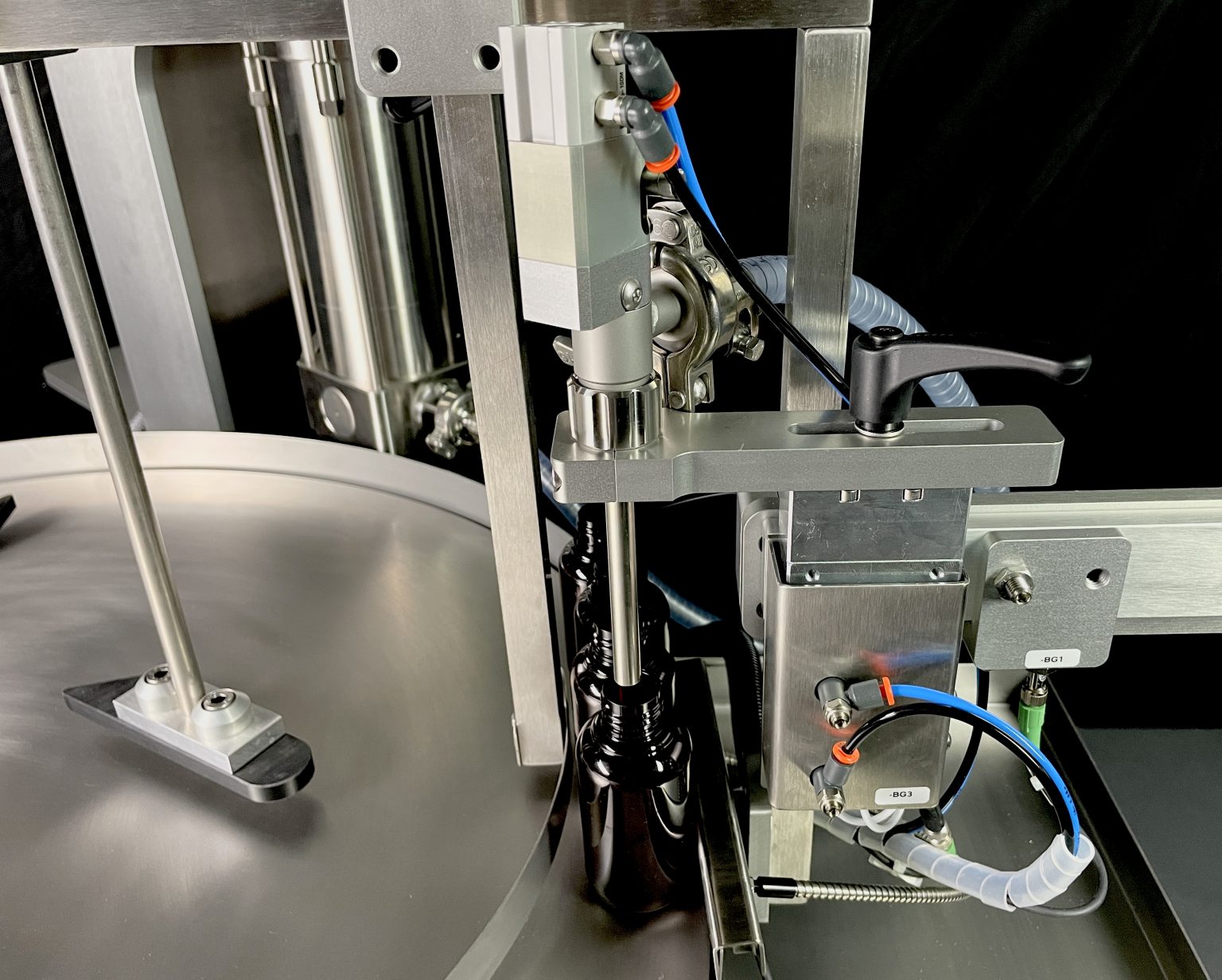

The dosing system ET 800 is equipped with a central rotary plate, split into two buffer areas, with a separation adjustable to different containers. Feeding to the dosing position takes place automatically. The safety function of the filling nozzle with pneumatic immersion avoids incorrect dosing.

With our servo piston dosing pump, a universal peristaltic or impeller pump, there are several precise dosing systems available with a large selection of accessories for a wide variety of dosing tasks.

The operation is performed via 7“touchscreen monitor. The programs can be created by the operators themselves and administered in the storage. Optionally, it is possible to provide production data output directly to your system.

- low space requirement

- mobile use

- different dosing systems

- Simple machine operation

- recipes programable by operator

Dosing system ET 800

Suitable for products

Diameter

∅ 25 – ∅ 80 mm

Height

max. 30 – 200 mm

Dosing volume

depends on dosing pump 3ml- 1000ml

Number of cycles

depends on filling volume and product

Technical data

Lenght

1100 mm

Width

1400 mm

Total height

1500 mm *

Work height

750-1040 mm

Weight

90 kg

Electronic

network voltage – 230 V, 0,6 kW * pneumatic connection – 6 Bar

All dimensions are approximate values

- Depending on the equipment of the machine