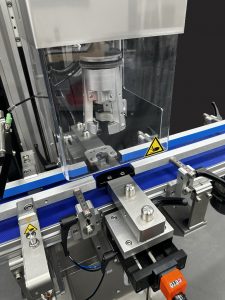

Screw capping machine VS 1650

This user-friendly capping system allows lids for bottles, jars, and other containers to be screwed on automatically. It helps protect your valuable employees and increases production capacity. Another major advantage is the electronic adjustment and monitoring of the tightening torque. The system can be connected to existing production lines or operated as a standalone machine. The combination of robust mechanics and modern electronics ensures long service life and consistent process reliability. With just a few adjustments, the system can be reconfigured for recurring tasks.

Options

- Product marking or labelling

- Buffer for not acceptable products in out-feed area

- Various grippers and gripping systems

- Production data output

- Combination with other systems

Automatic screwing

Reliable and user-friendly

The filled containers are placed on the conveyor either automatically or manually. In the first section, the lids are manually placed on the containers, then automatically singulated, screwed on, and transported to the discharge area. Pneumatic clamping using a prism ensures precise positioning and secure fixation of the container during the capping process. Operation is via a 7-inch touchscreen monitor. The operator can create programs and manage them in memory.

- 3-Jaw grippers with interchangeable jaws for different diameters

- mobile use

- Simple machine operation

- Servo screw technology

- 7“ Touch panel

- high process reliability due to electronic control

Technical data

Screw capping machine VS 1650

Length

1640 mm

Width

805 mm

Height

1730 mm

Weight

ca. 155 kg

Suitable for products

Diameter

Ø 23 – 100 mm

Height

50 – 250 mm

Product shape

Stable container

Number of cycles

Depending on product

All dimensions are approximate values.