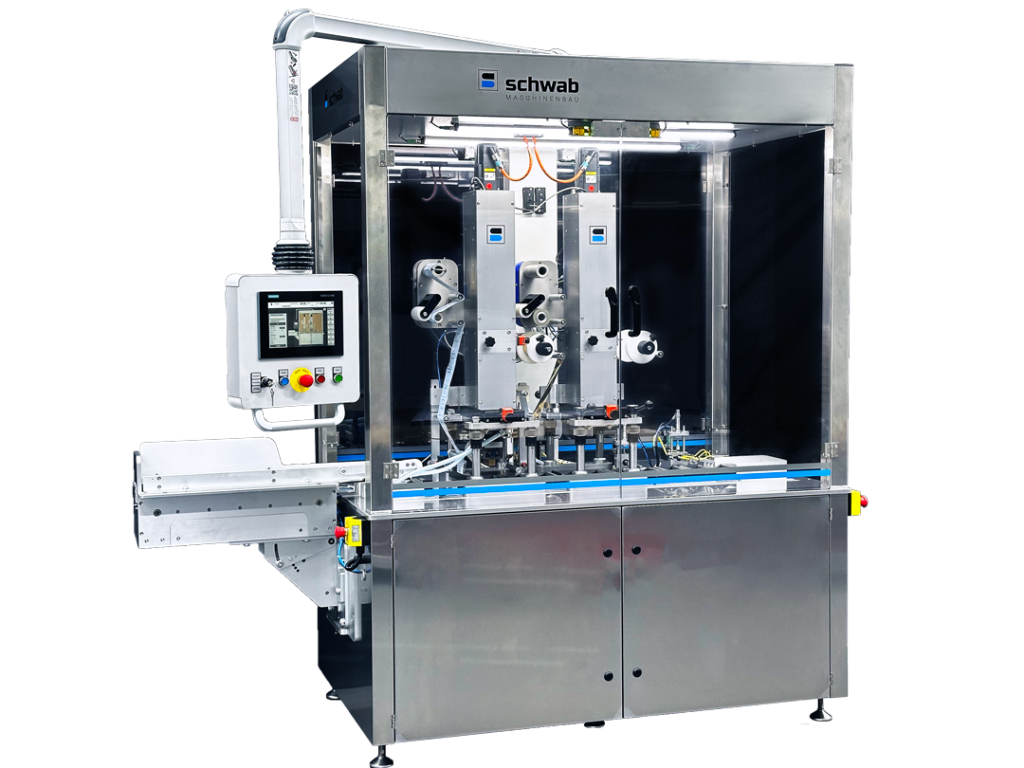

Hot stamping machine HP 32

Our hot stamping machine is the ideal solution for high-quality foil hot stamping in a roll-on process on cylindrical parts. State-of-the-art machine technology, stable and precise processing, as well as flexible adaptation to different products ensure consistently high print quality—even in series production. In addition, the system impresses with its long service life and cost-effectiveness.

Precise and stable

High print quality

The precision slides carrying the parts to be stamped run on hardened, ground guide rails through the stamping station. An optional second stamping station enables two-color stamping. Thanks to intelligent control combined with modern servo technology, a format change can usually be reduced to a simple stamp replacement. Consistently high quality is ensured by continuous, 100% monitoring of the stamping depth during production. To achieve the best possible stamp impression at all times, an additional camera inspection can also be integrated. Defective products are automatically and inline ejected—without interrupting the production flow.

- flat and wrap-around stamping

- short setup and changeover times

- stepless electronic stamping pressure control

- precise stamping depth dete-cation with automatic correction

- accurate mechanics

- Parameter input via touchscreen

- integrated program management

- automatic or fully automatic feeding system

Options

- inline 100 % inspection oft he stamping re-sult

- Extraction system

- can be combined with a plastic injection molding machine

- two-color printing with precise alignment

Technical data

Hot stamping machine HP 32

Length

2580 mm

Width

1020 mm

Height

2420 mm

Weight

ca. 950 kg

Cycle rate

55 Takte/min.

All measurements are approximate values.