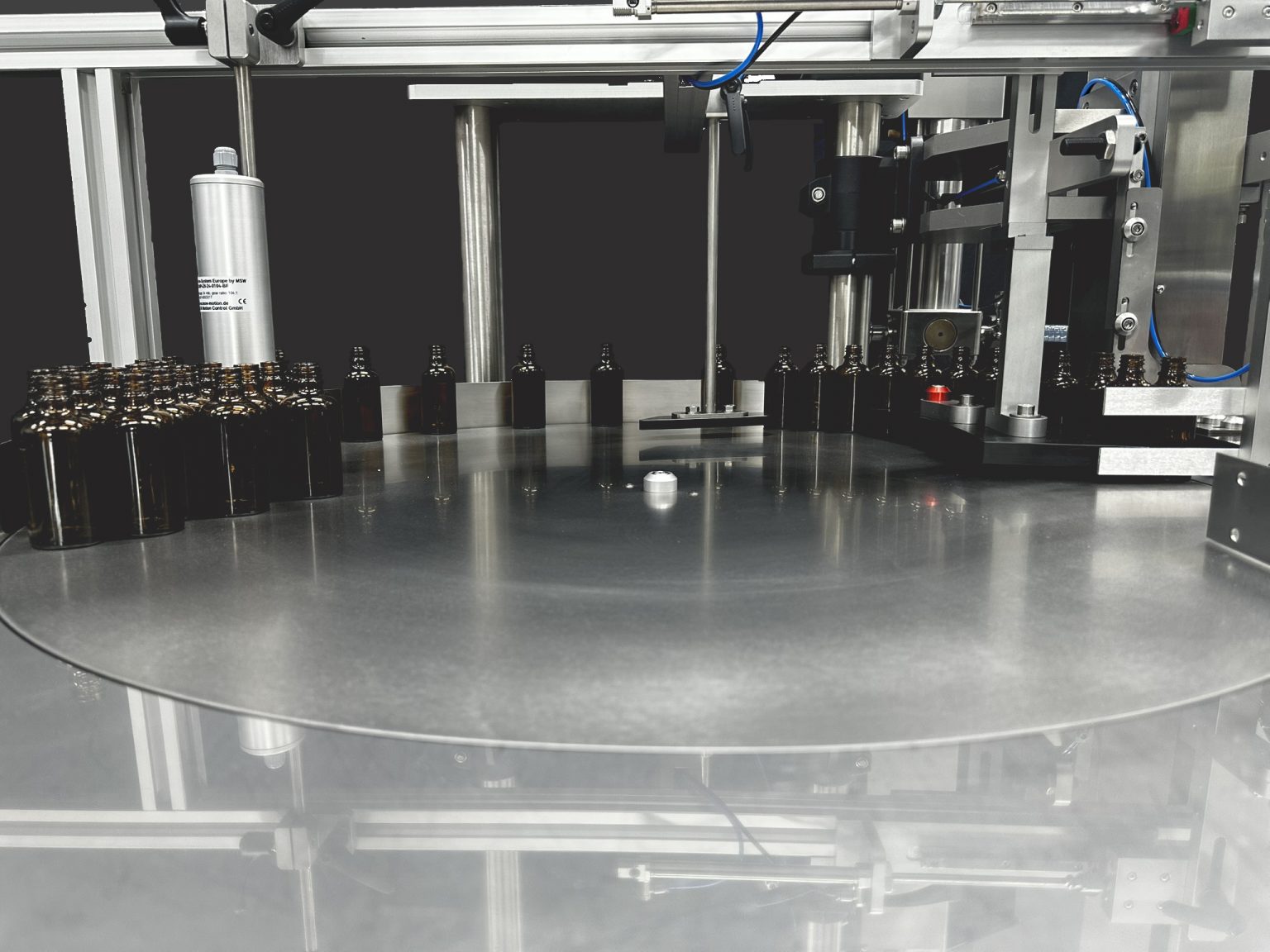

Dosing system ET 800 / ET 1000

The ET 800 / ET 1000 dosing system is a compact, versatile machine designed to facilitate and automate manual dosing processes. With a small footprint of only 1.5 m² and an adjustable working height for the entire machine, it can be used universally in nearly any production environment. The main advantages over manual single dosing are the automatic dosing process with programmable cycle times and the resulting free time for the operator to monitor the process while simultaneously performing other tasks.

The ideal complement

Compact and mobile

The ET 800 / ET 1000 dosing system features a central rotary table with a singulation mechanism adjustable to different containers. Transport into the dosing position occurs automatically. The safety function of the filling nozzle, with its pneumatic plunging movement, prevents dosing errors. With our servo piston dosing pump, a versatile peristaltic pump, or an impeller pump, multiple precise dosing systems are available, along with a wide range of accessories for a variety of dosing tasks. Operation is via a 7” touchscreen monitor. Programs can be created by the operator and stored in memory. Optionally, production data can be output directly into your system.

- Stainless steel design

- Mobile Use

- Different dosing pump systems

- Simple machine operation

- Recipes programmable by operator

- Low space requirement

- Program management for 200 recipes

Dosing system ET 800

Suitable for products with

Diameter

∅ 23 – ∅ 80 mm

Height

max. 270 mm

Dosage

Depending on dosing pump from 3 ml to 1000 ml

Number of cycles

Depending on filling volume and product

Product shape

Stable container

Technical data

Length

1100 mm

Width

1400 mm

Total height

1500 mm *

Working height

750 – 1040 mm

Weight

90 kg

Connection

electrical – 400 V, 0,6 kW *, pneumatical – 6 bar

All dimensions are approximate values

- Depending on the equipment of the machine